Rails in top conditions.

For Less Noise, Less Wear, and Greater Safety.

The noise and vibration emissions of rail vehicles are amplified by wear on the surfaces of rails and wheels. Roughness, waviness, and corrugations on the rail surface are therefore very important for quiet and low-vibration rail transport.

In practice, corrugations and waviness lead to increased mechanical stress on the wheel-rail-system and higher maintenance costs. Early detection of these wear effects is therefore crucial for ride comfort, safety, and infrastructure maintenance. Wear effects are typically eliminated by rail grinding. Proper grinding requires metrological acceptance. Infrastructure operators also monitor the condition of the infrastructure.

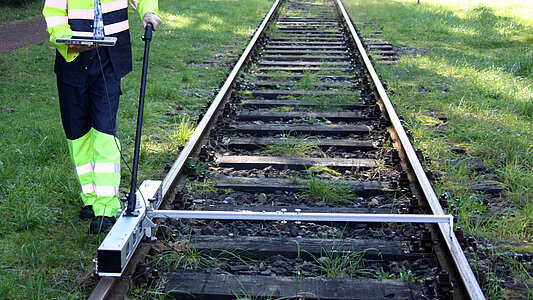

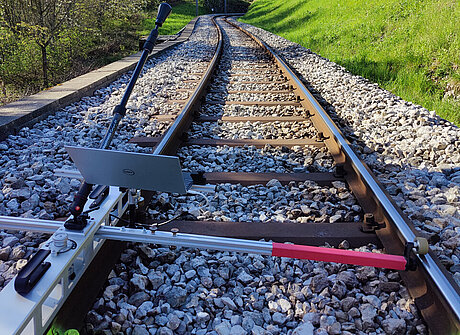

m|rail trolley is a mobile, high-precision measurement device for continuous, longitudinal measurements of the rail surface and the metrological processing of these tasks.

m|rail trolley Application Areas

- Normative quantification of track sections for acoustic homologation tests according to prEN 15610, EN ISO 3095, TSI Noise and EN ISO 3381

- Determination of input data for acoustic simulations

- Monitoring of the rail quality within the rail network

- Assessment of acoustic grinding

- Evaluation of rail grinding in accordance with EN 13231-3 (longitudinal profile)

- Detection of acoustic and vibration relevant defects (rail corrugation, slip waves)

- Research in the field of wheel-rail-contact

m|rail trolley Benefits

- High measurement accuracy and repeatability of measurements

- Quick installation of the device onto the rail

- Easy adjustment of the measurement track

- Direct measurement of the rail surface using displacement transducers

- Real-time display of the roughness signal

- Access to raw measurement data for further analysis

- Connection to the I/O device or measurement computer via USB interface

- Power supply via USB-port (no battery required)

- Continuous software adaptation to the applicable standards

- Product support is guaranteed for at least 10 years

One Device for Every Task

Measurement parameter

- Acoustically relevant rail roughness level Lr [EN 15610]

- Ripple formation (profile, amplitude, wavelength)

- Wave formation (profile, amplitude, wavelength)

- Longitudinal profile for evaluating rail grinding in accordance with EN 13231-3 (longitudinal profile)

Calibration

Measurements of rail and wheel roughness require the highest level of precision: irregularities of less than 1 µm must be reliably detected. m|rail trolley is calibrated with full metrological traceability according to EN 15610:2019 and meets the requirements for ISO/IEC 17025 accreditation.