Rethinking Wheel Monitoring:

Data-Driven. Predictive. Automated.

The Wheel Monitoring System automatically monitors the condition of wheels on rail vehicles, detecting wheel out-of-roundness and tread damage such as flats and polygonization.

Smart Maintenance

With the Wheel Monitoring System, predictive maintenance begins directly on the track: The system automatically identifies passing vehicles, analyzes tread defects on all wheels, and provides a precise condition indicator for each wheel. The recorded results support operational decisions regarding:

- Damage to wheel treads

- Distribution of wheel damages across the fleet

- Chronological development of wheel damages

By analyzing large amounts of data, damage patterns become visible and maintenance requirements can be identified at an early stage. This allows for systematic root cause analysis, targeted maintenance planning, and the prevention of unplanned downtime.

Typical consequences of wheel runout are:

- Increased noise: More than +10 dB due to flats and polygon formation

- Mechanical stress: Increased wear on axles, bearings, and superstructure

- Safety risks, especially on high-speed trains

- High maintenance costs: Unplanned interventions and high costs.

Wheel Monitoring System Application Areas

- Active noise and vibration protection

- Monitoring of vehicle fleets regarding the condition of the wheels of individual rail vehicles

- Support for condition-based maintenance for wheel sets,

including modeling for damage cause detection - Early detection of wheel polygons and wheel flats

- Development of long-term fleet strategies and optimization of maintenance

Wheel Monitoring System | Benefits

- Fully automated operation

- Detection of wheel tread defects (e.g., flat spots in accordance with EN 15313), wheel out-of-roundness, and wheel tread polygonization in accordance with UIC B 169/DT 405 and EN 15313

- Vehicle identification and wheelset detection

- Support in determining the optimum cutting depth for wheelset turning

- Noise measurement module

- Customized software with graphical user interface for condition data

- Real-time data transmission via LTE, Ethernet, and fiber optics

- Guaranteed support for at least 10 years

Intelligent Monitoring of each passing wheel

Technical Design

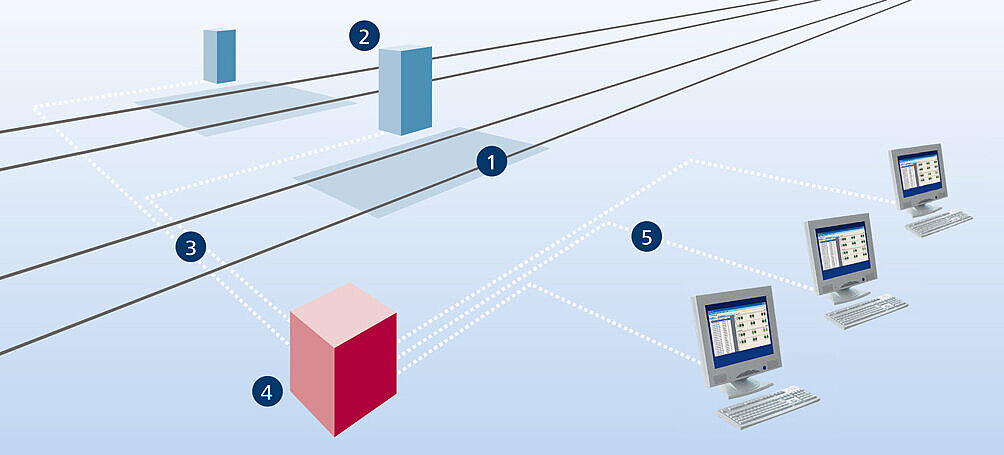

Installation in the track area is quick, robust, and non-invasive. Specifically designed WMS sensors measure the wheel tread condition of each passing wheel. A vehicle identification system registers the vehicles with their ID numbers. Optional microphones can record noise emissions to detect malfunctioning aggregates, for example.

Precise Results

As a track-side monitoring system that detects wheel irregularities during operation, the WMS determines the indicators for polygonization and flat spots for all wheels. The values displayed are proportional to the severity of the tread damage and can also be adapted to the user's requirements.

Option: Mobile Wheel Monitoring System

The mobile WMS offers all the advantages of a fully automated WMS at an attractive price with a shorter installation time. It is ideal for quickly assessing the quality of wheel tread conditions across the entire fleet.

- Track measurement station and

- Measurement unit

- Automatic measurement of all passing vehicles

- Vehicle identification

- Data compression

- Data transfer

- Data transfer to database

- Analysis unit and database

- Data analysis

- Storage of all data

- Webapp WMSInfo

- Identification of wheel damage

- Condition-based maintenance

Option: Mobile Wheel Monitoring System

The mobile Wheel Monitoring System offers the benefits of a fully automated WMS at an attractive price. It is designed to monitor wheel damage such as polygons and flats, as well as their progression over time. Temporarily installed, it identifies passing vehicles, analyzes wheel tread quality, stores results in a database, and delivers clear, reliable results on:

- the condition of the wheels within a rail fleet

- the distribution of wheel damage

- the development of wheel damage

The datasets collected by the mobile WMS can also be used for statistical analyses to identify the root causes of wheel damage.